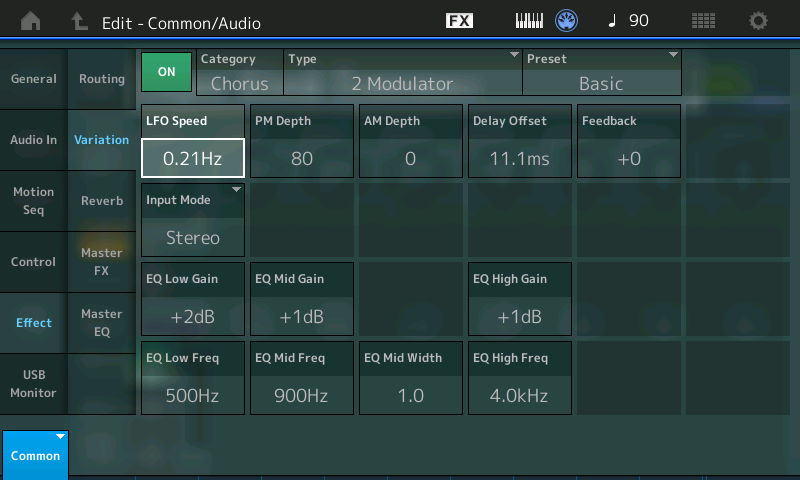

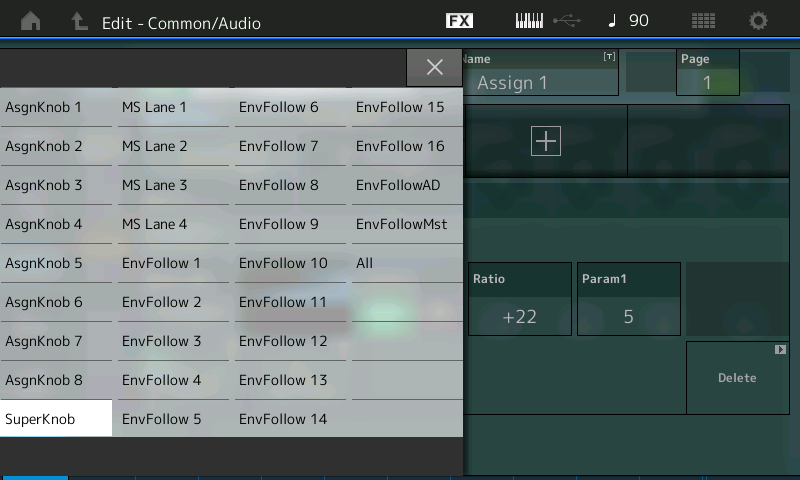

Listen while moving the Super Knob to the right; This increases the

LFO Speed (Ratio is +22, the positive value indicates how steep the change is) and decreases the

PM Depth (Ratio -19, the negative value indicates how steep the decline is). The

LFO Speed starts at

0.21Hz and will increase from there. While the

PM Depth starts at a setting

80, the

-19 (negative value) setting ensures it will be decreased from there – the RATIO determines what happens (direction and depth of application) to that parameter as the Super Knob is moved from minimum (0) toward maximum (127).

Because the Common Assign Knobs are routed automatically to the Super Knob only the two assignments for Knob 1 + 2 are needed here.

Experiment with different values for both the Ratio values and the initial LFO Speed/PM Depth values to gain an understanding of what you are changing and how they interact.

Param 1 (Parameter 1) – experiment with this and observe how it changes the incline of the application of the control. It alters the shape of the Curve! So turning the Super Knob does not have to be a straight line increase or decrease (not at all), you can customize this “curve type” by an astounding degree – additional “Parameters” will be added according the Curve Type selection; more on that in a future article. For now let’s just stick to the Standard Curve.

EXPERIMENTS

Important Hint: If LFO Speed is initially set to 0.0Hz you will hear no modulation when the Super Knob is set to 0. By having an initial setting of 0.21Hz there is a slight movement to the sound initially. This, of course, is a programming preference. Often you want a certain amount of movement to start, and then have the controller adjust that amount. Controlling the range of application is a programmer’s choice.

Try this: Highlight and adjust the LFO Speed parameter directly to hear its adjustment to the speed of modulation from a minimum of 0.0Hz to a maximum of 39.7Hz. You can do so by highlighting the parameter directly in the Variation Effect screen (above) and use the Data Dial to change the actual setting value. The initial setting of 0.21Hz is approximately one cycle every 5 seconds – as you approach 20 times a second, you will notice that the speed of modulation/movement itself is creating a low frequency pitch of its own – it practically becomes a buzzer – at the maximum of 39.7Hz the LFO is an audible oscillator. The LFO crosses over from being a (low frequency) “rate” into being an audible pitch.

Next, try this at different settings for the

PM Depth. Notice that if

PM Depth is

0, naturally, you hear no modulation, no matter what the speed.

Here’s a theoretical situation where this programming would be used: You want to increase the LFO SPEED but not have it go into the bizarre (pitch) range that happens as you approach maximum speed. So you want to increase the Speed but decrease the Depth, simultaneously! (This is a job for either two hands, or the Super Knob!)

This is just one of many different scenarios for assigning items to the Super Knob. One gesture accomplishes multiple things.

Summary: Here we have learned that COMMON Assign Knobs 1-8 are automatically assigned to be controlled by the Super Knob. The significance of this will become more clear when we begin to program the PART 1-8 Assign Knobs 1-8, where you can assign a PART parameter to an Assignable Knob and then link the Part’s Knob to the Super Knob.

Depending on your front panel EDIT selection (COMMON or PART 1-8) the Assign Knobs 1-8 take on different roles. If you envision a full front panel – every Knob is a separate entity – you would have 8 Assign Knobs for the COMMON edit parameters, you would have 8 Assign Knobs for PART 1 edit parameters, another 8 Assign Knobs for PART 2 edit parameters, another 8 Assign Knobs for PART 3 edit parameters, and so on. That would be a total of 72 physical Assignable Knobs in a Keyboard Controlled Performance.

Now the reason for the Super Knob comes into focus. You would probably never need to assign this many controls to a single playable sound _ it would be difficult for your ear/brain to take in what was happening. But if you think of the 8 Parts of a Keyboard Controlled Performance program as one big modular synth that has 64 Oscillators, 64 Filters, 64 Filter EGs, 64 Amplifiers, 64 Amplitude EGs, etc., etc., etc. you begin to understand the scale and scope of the controller matrix on tap here with MONTAGE. The word “massive” is not hype.

Each PART can have 16 assignable Destination (parameters) for the various controllers – you also have Assignable Switches 1/2, Ribbon, Mod Wheel, PB Wheel, Foot Controllers, Aftertouch and more. You can choose to use the Assignable Knobs directly or linked to the Super Knob. You can assign functions to multiple controller or spread them out as you desire. As we go deeper into the Motion Control Synthesis Engine we will explore these possibilities. And pickup some tips on how to navigate and view exactly what’s going on. We highly recommend you take your time – unfold this a layer at a time.

In the example above, we see that the Super Knob can control multiple parameters simultaneously to achieve a specific result – in this case, the Chorus’ LFO speed is increased, at the same time its Depth is reduced. By adjusting the CURVE you can fine tune this dual action with a single controller gesture.

EXTRA CREDIT: Using the navigation Shortcuts

Shortcuts: Call up the PERFORMANCE “Super Knob Common” and press the HOME icon.

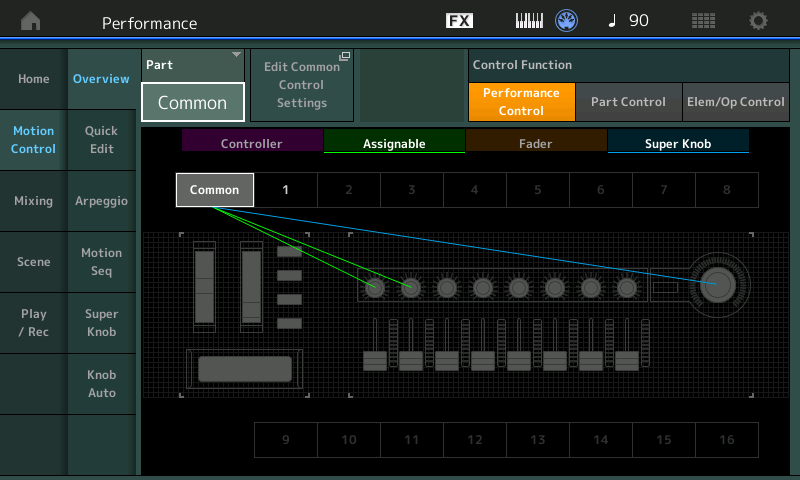

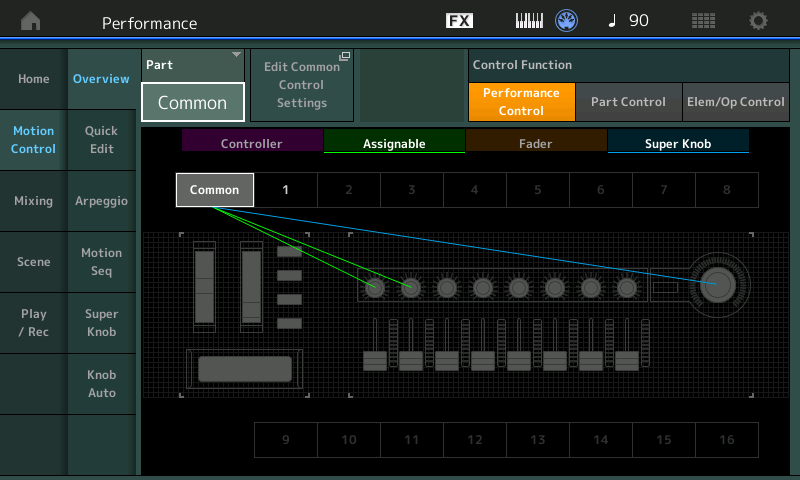

Press [SHIFT] + [INFO] (HOME) buttons to jump to the Motion Control OVERVIEW screen. (Shown below)

Here you can select to view Controller Wheels/Ribbon, Assignable Knobs/Buttons, Fader, and Super Knob assignment. Touch those words directly in the screen to toggle its connectors on and off. Shown are the “Assignable” Knobs (green) and the “Super Knob” (blue). Turned off in the viewer are the “Controller” and “Fader“. You can see how the two knobs and the Super Knob are linked to COMMON.

TIP: In the “Part” box the word “COMMON” appears, change this using the [INC/YES] button or the DATA DIAL. You can select any of the numbered Parts 1-16 (Assignable Knob parameters are available for PART 1-8). Please notice how changing the value from “COMMON” to “PART 1”, “PART 2”, and so on, actually changes the lighted front panel buttons on your right front panel. Selecting Parts, even selecting ‘Common’ can be done in the screen or by pressing an available corresponding button. Begin to make sense out of the lighted buttons. They always tell a story about what’s going on in your screen!

- Return the item to “COMMON” on the OVERVIEW screen.

The box next to the PART > COMMON is a direct shortcut to the Controller Setting screen of the currently selected Part: “EDIT COMMON CONTROL SETTINGS”.

Touch “Edit Common Control Settings” to drop directly to the Common Edit Control screen.

This shortcut from the Controller Assignment jumps you directly to the controlled parameter.

“Aha!”

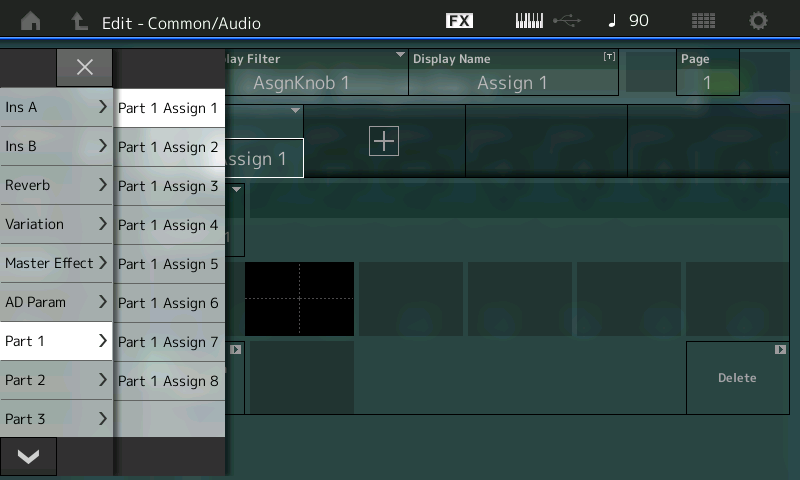

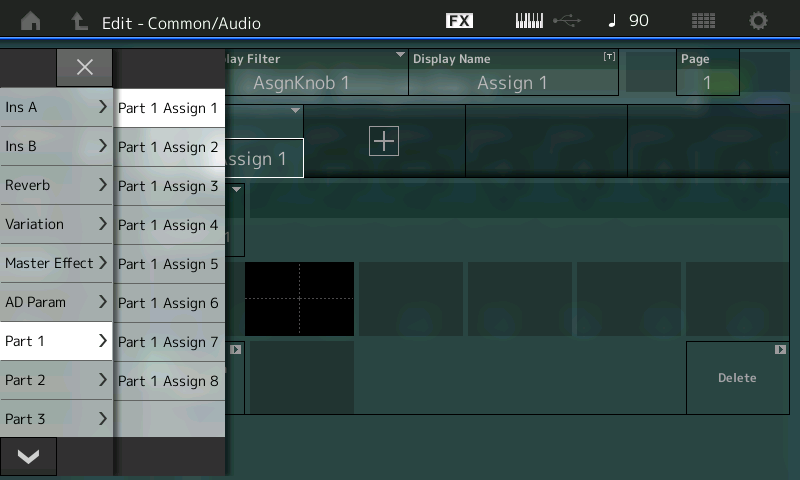

POWER TIP: Once you arrive on the Controller Settings screen, you can view the 16 assigned Source/Destination functions to any ‘Part’ or to the ‘Common/Audio’ level, four at a time, by highlighting the DISPLAY FILTER box and selecting to view “ALL”. (Shown below).

Use the PAGE function to view up to 16 Destinations per programming level. MONTAGE will keep track of the number of assignments per ‘Part’ and for the ‘Common/Audio’ level of editing. The “+” sign in a Destination box would allow you to ADD a new Source/Destination parameter assignment. The “DELETE” box in the lower right corner will remove the selected Source /Destination assignment.

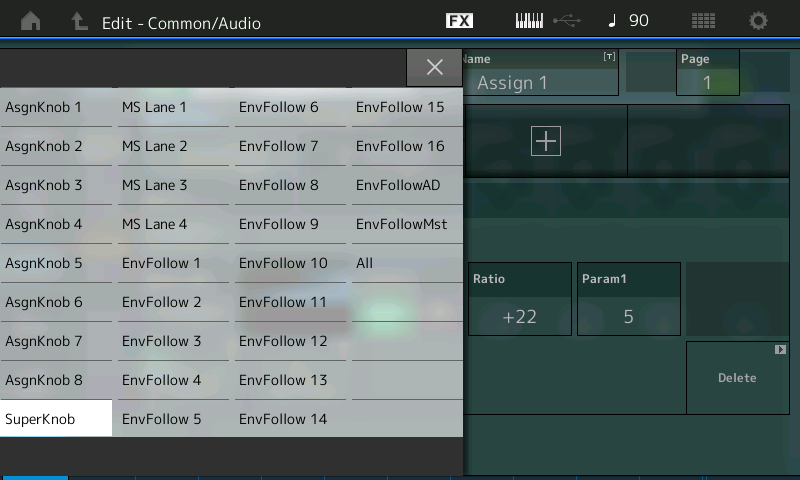

If the [AUTO SELECT] is green, you can move a controller to see what is assigned to it or you can move the cursor to the DISPLAY FILTER box and use the Data Dial to view the available options (shown below). This Display Filter allows you to *view* assignments made to a specific controller – this must be stated less you believe you are making an assignment – when you change the Display Filter you are changing what you are viewing.

New in version 1.60 and later, you can view all items assigned to the SUPER KNOB. This greatly simplifies finding what parameters are being changed when you move the Super Knob.

It is a Display *Filter* because it is allowing you to see just what is assigned to the various CONTROL SOURCE options:

• Assign Knobs 1-8

• Super Knob

• Motion Sequence Lanes 1-4

• Envelope Follower Parts 1-16, the AD, and the Master.

All:

In this first programming example, we see how the Super Knob is linked to COMMON and that COMMON is assigned to vary two Destination parameters. The Destination 1 box is assigned to control the Var LfoSpd. The box with a “+” sign will allow you to ADD a control routing (called a Destination). The “DELETE” box in the lower right corner will allow you to undo a Destination. There can be 16 Destinations (assignments) per PART. Destination 2 in our example assigns Assignable Knob 2 to Var PmDpth.

At this upper COMMON/Audio level of the architecture this includes the following PARAMETER DESTINATIONS:

• INSERT A (when assigned to the A/D INPUT)_

• INSERT B (when assigned to the A/D INPUT)_

The significance here is that you can control, in real time, the Insertion Effects that are assigned to the A/D INPUT Part. Each MONTAGE PART (including the A/D Input) has its own dedicated dual Insertion Effect processor – which now can be automated by the Motion Control Synthesis Engine. A Microphone can use a pair of Insert Effects (a Delay LCR and something else) and you can, for example, control the Dry/Wet Balance and number of repeats (Feedback level) by assigning control to one or more of the available COMMON Assignable Knobs

• REVERB (System Effect)

• VARIATION (System Effect)

The significance here is that on the top COMMON level, all eight Parts can be influenced, or not, depending on how much signal you send into the shared System Effect processors. In other words, every PART has a SEND amount into the Reverb and Variation processors, you determine *how much* per Part. Effect parameters for the chosen Effect TYPE will be available as assignable Destinations. We see this in the first example where we are controlling parameters within the 2 Modulator Chorus TYPE.

• AD INPUT Parameters

Here you can control the VOLUME, and SEND amounts to the Reverb and Variation SYSTEM EFFECTS for the AD INPUT Part. This gives you full automation of audio signal coming into MONTAGE – which could be anything you place in front of a microphone or another keyboard, or other playback source.

• MASTER EFFECT

The significance here is that you can automate control over the Master Effects – making it a PART of the Motion Control situaton.

• PART 1 – AS1 through AS8

• PART 2 – AS1 through AS8

• PART 3 – AS1 through AS8

• PART 4 – AS1 through AS8

• PART 5 – AS1 through AS8

• PART 6 – AS1 through AS8

• PART 7 – AS1 through AS8

• PART 8 – AS1 through AS8

• PART 9 – AS1 through AS8

• PART 10 – AS1 through AS8

• PART 11 – AS1 through AS8

• PART 12 – AS1 through AS8

• PART 13 – AS1 through AS8

• PART 14 – AS1 through AS8

• PART 15 – AS1 through AS8

• PART 16 – AS1 through AS8

It is very important to understand these assignments. They allow the Super Knob to control specific items within each separate PART. We stated at the beginning, the Super Knob automatically controls the eight COMMON Assignable Knobs 1-8 and it works directly on those upper level/shared parameters. Notice that listed here is each of the 8 Keyboard Controlled PARTS, and each of their 8 Knobs. This means with an assignment selection here, you are linking the individual PART’s control of a Destination parameter to the movement of the Super Knob. Additionally, any of the 16 PARTS, even those not directly under the KBD CTRL, can still be affected by the movement of the Super Knob (via changes to the shared System and Master Effects).

In our next example, we will see how this intermediate step opens the door to a wide, wide world of synth patching. We will drop down a level to the individual Part and parameters that will only affect a single Part within a Performance. We will assign PART 1’s Assignable Knob 1 so that it follows the movement of Super Knob and yet controls a parameter exclusively (locally) within just one Part, PART 1. The selection of potential Destinations will change and will include parameters specific to this particular PART as an individual component within the PERFORMANCE.

If you have any questions or comments about this article, please join us to discuss them on the Forum here.

Catch up on the previous article in the series – “Mastering MONTAGE 1: The Super Knob”

Next Article: “Mastering MONTAGE 3: Super Knob Unipolar”